Berd Spokes: Show & Tell

Comparisons to other spokes

Let’s take a look at Berd spokes in comparison to other spokes that we commonly use in our wheels.

The DT Swiss Competition is a double-butted steel spoke measuring 2.0mm at the head and thread and 1.8mm in the centre section. We use these for most wheelbuilds with aluminium rims.

The DT Swiss Aerolite is a bladed spoke with a 2.0mm head and thread and a flattened 0.9x2.1mm centre section. We use these spokes for almost all carbon wheel builds.

Berd Polylight spokes use a standard 2.0mm threaded steel section at their nipple, but the rest of the spoke is made from Ultra High Molecular Weight Polyethylene (UHMWPE). Their centre section is 1.8mm in diameter.

UHMWPE

Ultra High Molecular Weight Polyethylene is a high tech string-type material. It’s used in a variety of products like climbing ropes, ship sails and rigging, spinal impact, hydraulic seals, and cycling shoes. It’s incredibly lightweight, abrasion resistant, and flexible - all properties which make it great for spokes.

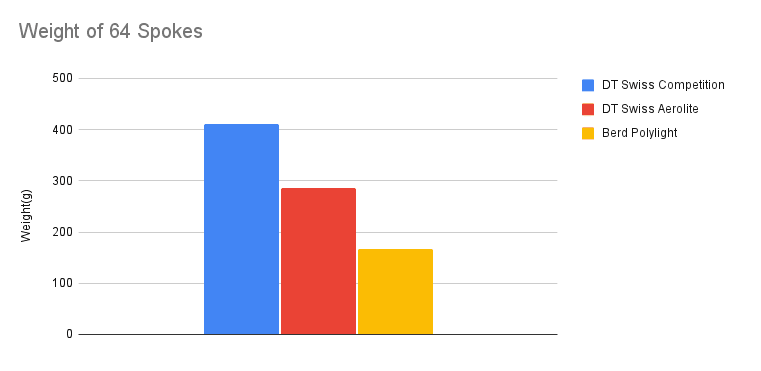

Weight

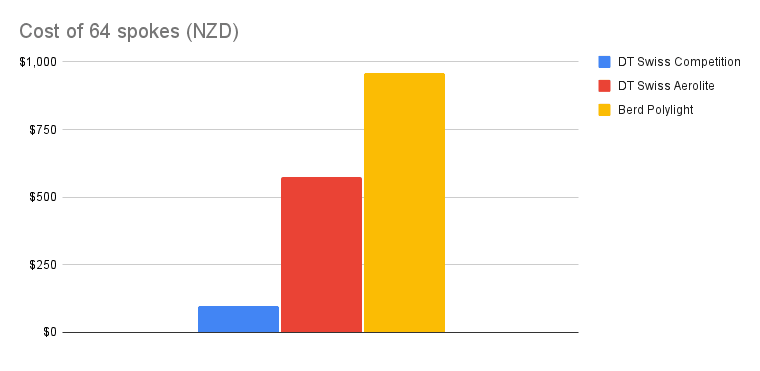

Cost

Berd spoked wheels are more expensive due to lack of economies of scale in producing spokes, and a significantly higher wheelbuilding time.

As Berd continues to grow and produces more spokes we’re anticipating the spoke cost to come down.

A huge chunk of the time building Berd spoked wheels is in lacing the spokes into the hubs - a process more like putting thread into the eye of a needle than traditional wheelbuilding. Hubs with Berd specific hooked flanges help reduce this additional time, but then they come with their own complexities regarding low economies of scale.

The flexible nature of the UHMWPE means tensioning and truing of Berd spokes takes longer than with steel spokes. As we build more Berd spoked wheels and learn more about their unique building requirements we’ll be able to further modify our build procedures and will be able to further invest in Berd-specific wheelbuilding tools and processes to help, however it’s unlikely that the time to build a Berd spoked wheel will ever approach that of a traditional steel spoke wheel build.

Reducing lacing and wheelbuilding time is the primary reason for the straight-pull spokes used in many factory-built wheels so it’s unlikely we’ll see factory-built Berd spoked wheels any time soon.

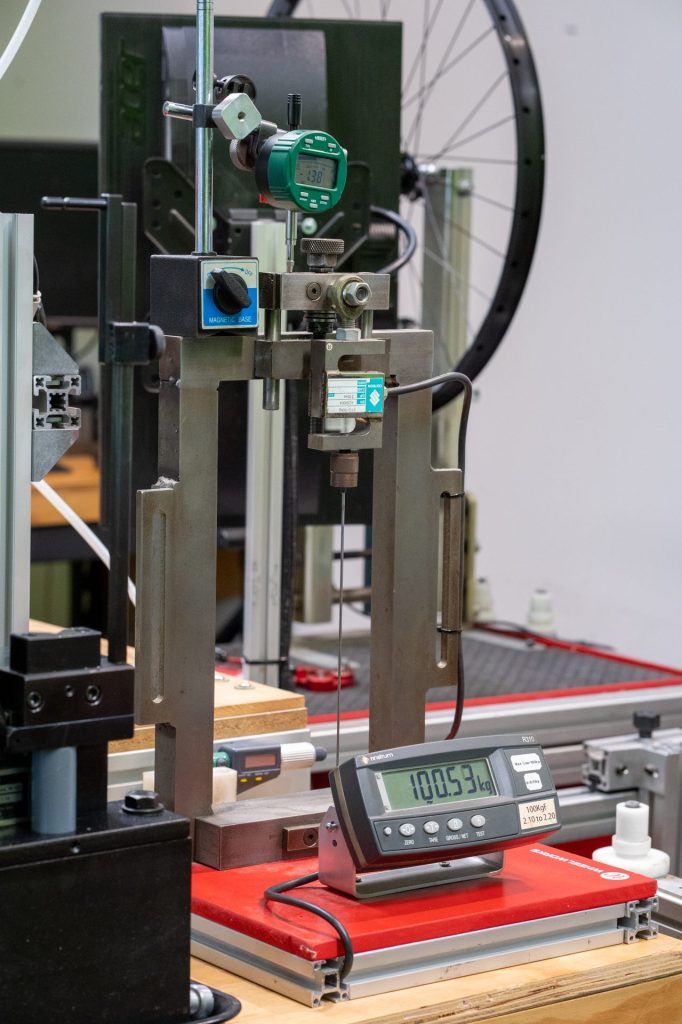

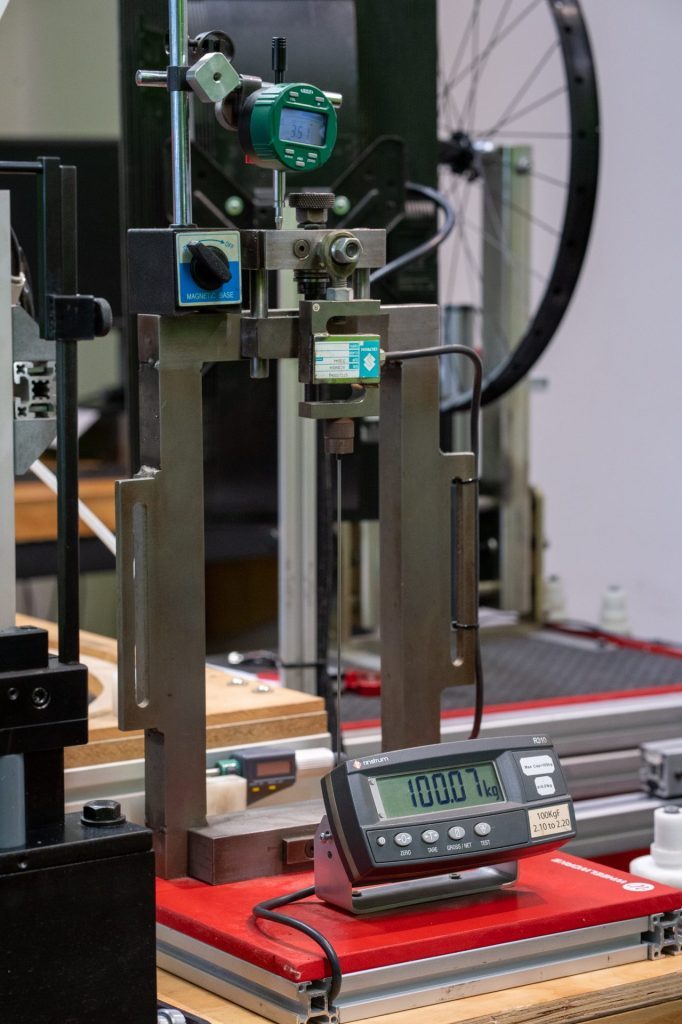

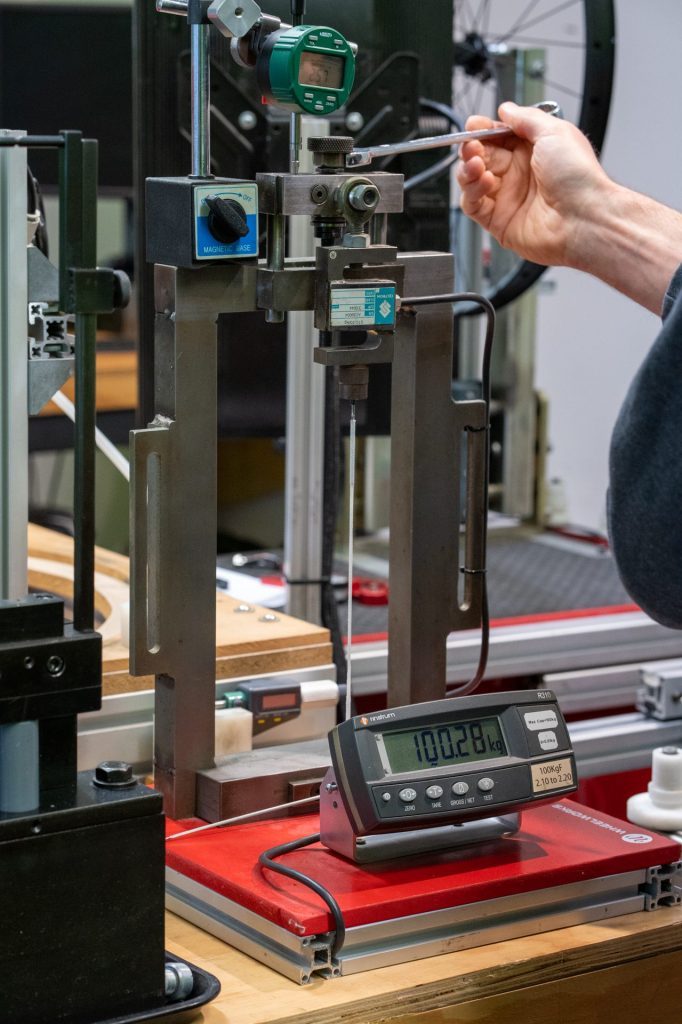

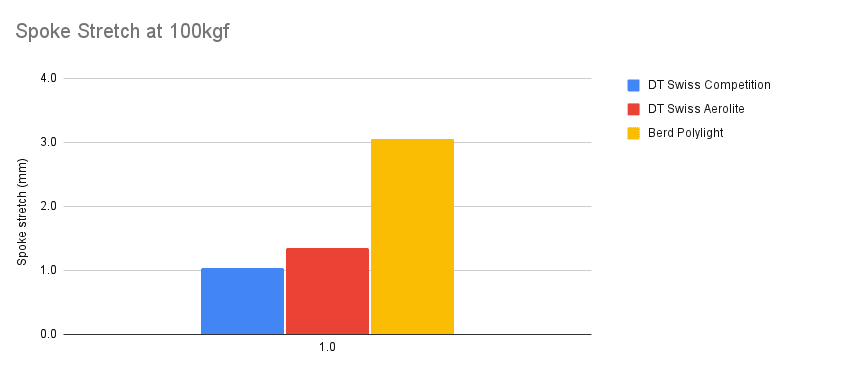

Spoke Stretch Under Tension

We tested each spoke by applying 100kg of force to each to simulate how they might stretch while riding a wheel built with them. As you can see, Berd spokes stretch quite a bit more than steel spokes.

Aero

We’re yet to see any CFD or wind tunnel testing of Berd spokes compared to an aerodynamic steel spoke, but their larger diameter indicates they will perform similarly to a spoke like the DT Swiss Competition but won’t be nearly as aerodynamically efficient as bladed steel spokes.

This means Berd spokes are unlikely to be used in go-fast road wheels where reducing aerodynamic drag is a main requirement.

Stick-in-Spoke Resistance

Berd’s own testing shows their spokes are significantly more durable in “stick in the spoke” tests than steel spokes because of the super flexible UHMWPE material.

This makes Berd spokes a great option for wheels which will be used in remote adventures.

In the Field Repair

Berd spokes are less likely to be damaged by “stick in the spoke” type incidents than steel spokes, however if they are damaged they are more difficult to replace, and require more tools to do so.

A replacement steel spoke of the correct length can be used in an emergency situation.

Colours

Steel spokes come in either raw stainless colour or in black. Contrary to popular belief the black spokes are not anodised but are created using a heat-treating process which is confusingly called “bluing”.

For the feature spokes at the valve we custom powder coat the steel spokes in white or red.

Berd spokes are white due to their raw material colour. They can be coloured using the Berd colouring kits.