Maker Disc Carbon

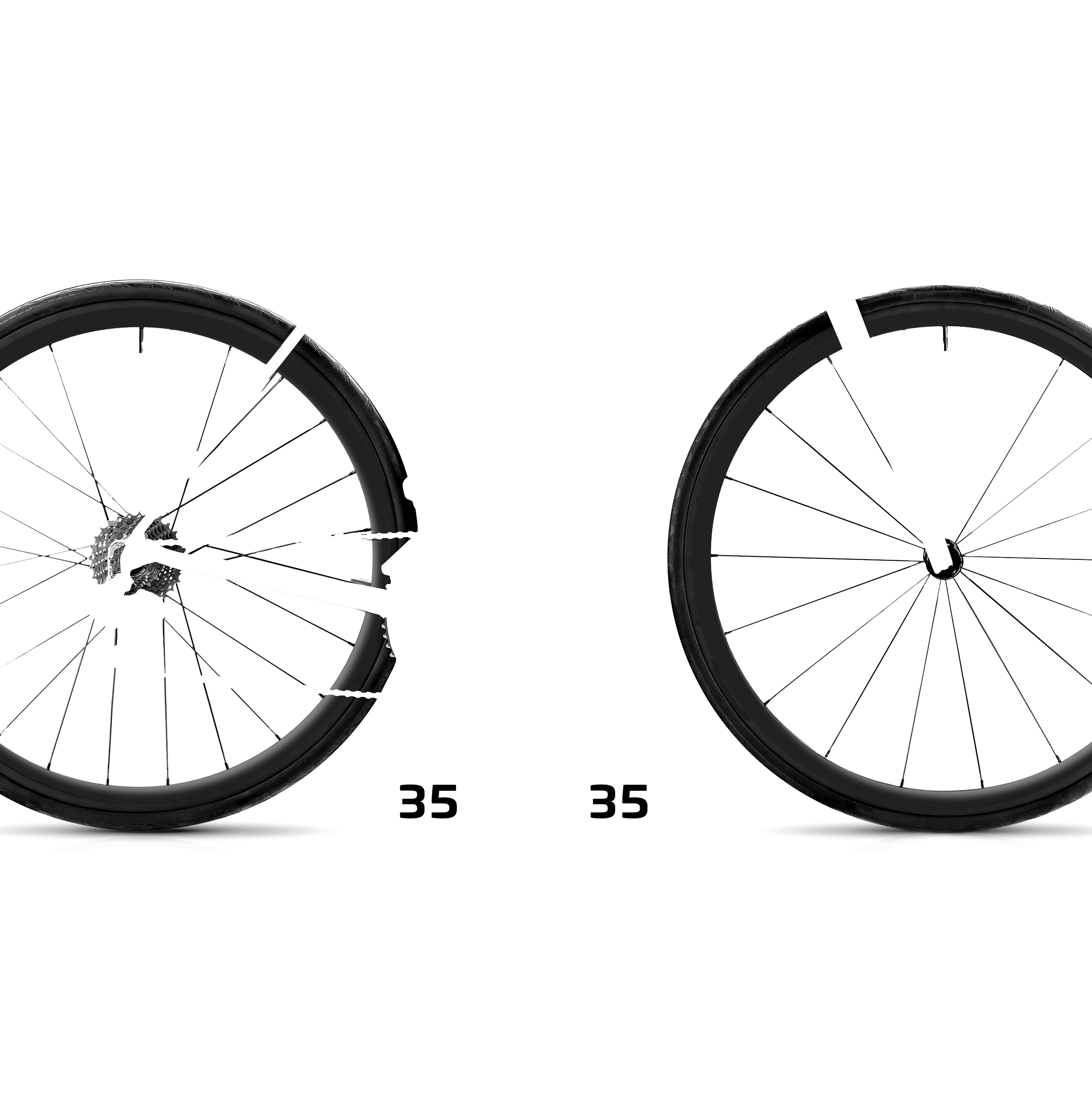

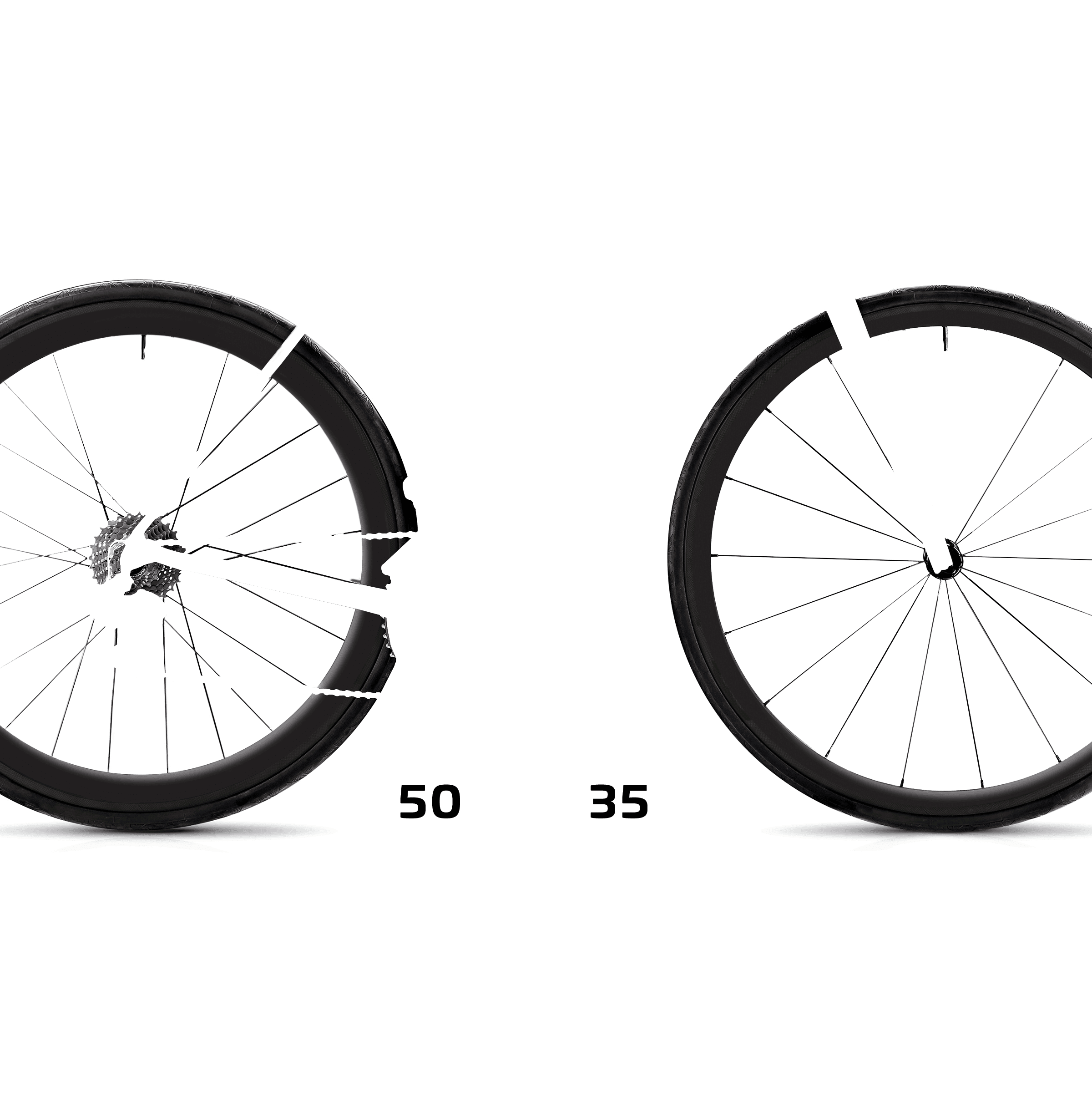

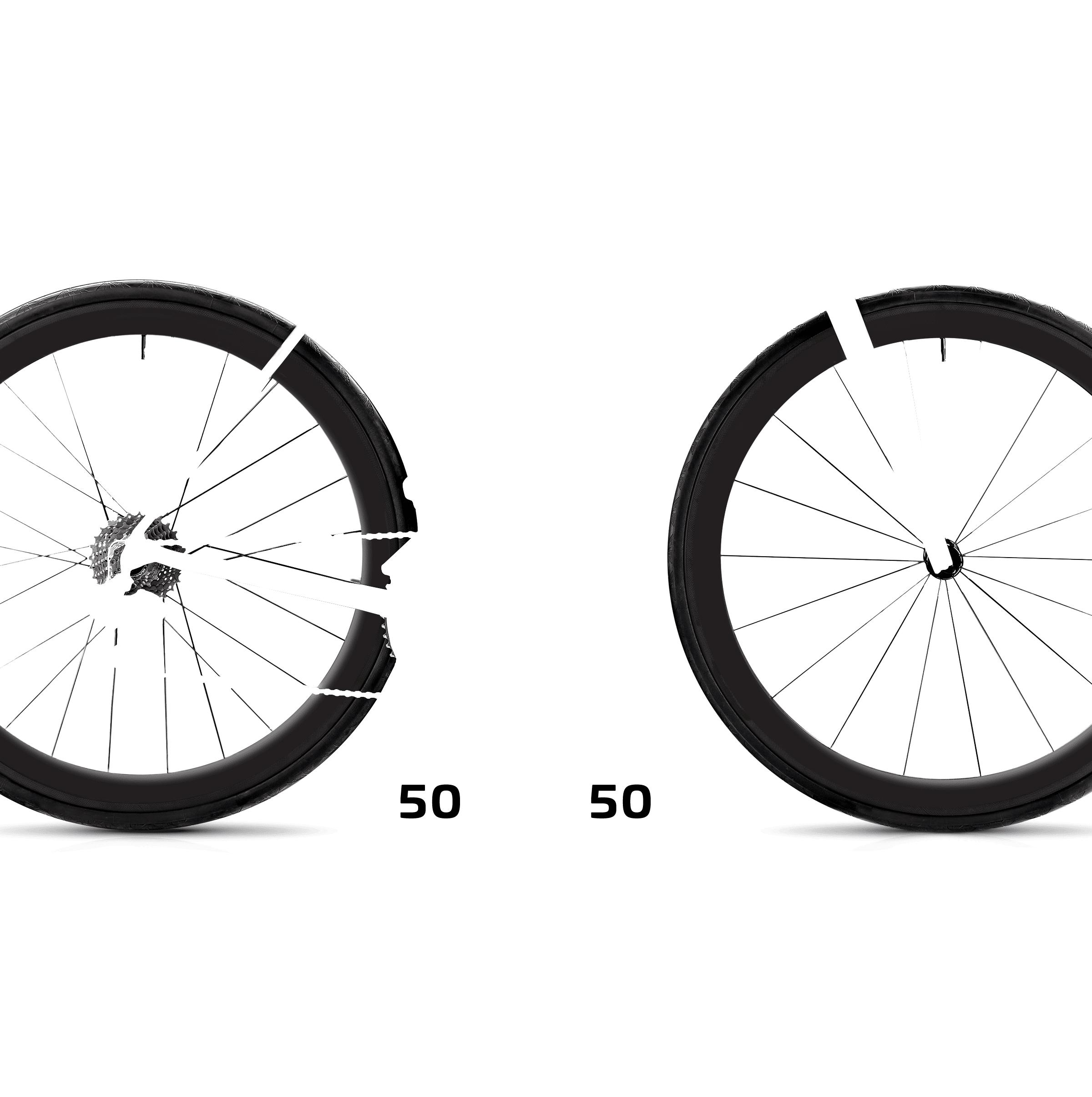

A high performance 35mm or 50mm customised carbon wheelset guaranteed for life and designed for the modern generation of disc brake equipped bikes.

Use this Builder to customise your own wheels. Buy online or speak to a friendly sales rep. Don't worry if you're not sure - after you place an order we'll call you and talk through the choices you've made to ensure everything is correct!

Builder FAQ

Learn more about how our popular leasing program works: 18 Month Wheelset Leasing

If you're not sure, watch our video on the difference:

Hub selection involves balancing usage, weight, dimensions and aesthetics. Learn more about each hub brand we offer for this build below. If you're after something else, or aren't sure, get in touch and we can help with options.

If you're not sure, check out our Hub Width Explained page.

If you're not sure, check out our handy guide.

Have More Questions?

Chat with one of our specialists to dial in the perfect build for you.

Learn More About Wheelworks Components

Rims

Custom rims for custom wheels. Learn how our Maker Disc Carbon rims are made here.

Spokes

We use DT Swiss spokes because they're the best. Learn more here.

Learn about our homegrown hub. Modular, lightweight and high-performance.

We offer DT Swiss Hubs. Learn more at Here.

We offer Chris King hubs. Learn more at ChrisKing.com

We offer White Industries Hubs. Learn more at WhiteInd.com

After Sale Support

Our commitment to you doesn’t end once you've got your wheels. If you have any questions maintaining or servicing your wheelset we’re here to help. Just reach out on our Contact Page.

Build Process

Wheelbuilding is our passion, we like to think we're pretty damn good at it too. Learn about our process, tooling and expertise.

Lifetime Guarantee

We guarantee Wheelworks wheels for life because we know they will last. Learn more about our Warranty here.

Road Tubeless

All of our rims are tubed and tubeless ready. Not sure about tubeless? Check out our video:

Looking For More?

We love chatting about our Wheels and have lots of information to reference. Give us a call if you've got additional questions!